|

Scientists by decades fought above the decision of problem of quality of superficial layer of details of machines management at polishing. To 35-40% expensive details, having high exactness after polishing, went away to defective marriage. Reason – hidden from the eye of prizhogi and mikrotreschiny, arising up at treatment of metals and alloys abrasive instruments under act of high temperatures in the area of cutting. Multimillion-dollar losses were perceived as an inevitable evil. Even selection of understated, so-called «sparing», polishing modes, in once or twice reducing the productivity of treatment, did not allow fully to remove shlifovochnye defects. As a result longevity of bearings went down in 3 times, gear-wheels – in 5-8 times, firmness of stamps – in 30 times. Approach of the systems to the decision of complex problem allowed already in those years to carry out a breach in technology of polishing of responsible details of machines and formulate basic directions on automation of polishing machine-tools and technology of making of abrasive instrument. Method of the irregular polishing, offered the group of scientists allowed to decide a problem. In the Odessa polytechnic university two basic scientific directions of research works were finally formed on a management the processes of abrasive-diamond treatment: bringing in the technological system of new structural-technological elements (irregular polishing, uprugodempfiruyuschee fastening of instrument, new technologies of correction of diamond-impregnateds, technological lubricating compositions etc.) and automatic (adaptive, intellectual, computer) process control diamond-abrasive treatment on the basis of the use of information, arising up at treatment. The department of technology of engineer of ONPU the last years conducts the complex of research works on an analysis and synthesis of technological processes of making of gear-wheels. Fundamental theoretical developments are executed on the study of thermodynamics processes, flowings in the area of contact of diamond-impregnated. This information is needed for creation of new more progressive methods of polishing of gear-wheels, allowing to increase the productivity of treatment and stabilize cutting ability of circles and quality of poverkhnosnogo sloya.

| | Akimov V.L. Internal polishing / V.L. Akimov, V.I. Mucyanko. - L. : Engineer, 1986. - 128 p. : il. -

(B-chka of polisher, inst. 4) Technology of the internal polishing is considered in a brochure. The constructions of machine-tools are described for the internal polishing with CHPU. Dany of recommendation on the choice of new abrasive materials and circles for hard-processing materials. Information is resulted about lubricating-coolings liquids (SOZH).

Technology of the internal polishing is considered in a brochure. The constructions of machine-tools are described for the internal polishing with CHPU. Dany of recommendation on the choice of new abrasive materials and circles for hard-processing materials. Information is resulted about lubricating-coolings liquids (SOZH). Brochure is intended for workers-polishers, setter-ups and masters.

|  | | Al'perovich T.A. Construction of polishing machine-tools : text-book for PTU / T.A. Al'perovich, K.N. Konstantinov, A.Ya. Shapiro. - M. : High school, 1989. - 288 p., il. The constructions of polishing are considered, features of machine-tools with CHPU, industrial works, methods of basing and treatment of model details; resulted taking about the indexes of reliability of polishing machine-tools and their productivity. Textbook can be used for the vocational training of workers on a production. |  | | Quality and productivity of abrasive-diamond treatment: studies. manual / A.V. Yakimov, F.V. Novikov, G.V. Novikov, A.A. Yakimov. - O. : ONPU, 1999. - 212 p. The technological methods of increase of cutting ability of circles and improvement of quality of superficial layer are given in a train aid. The methods of polishing process control are offered. Intercommunication of the productivity and exactness of treatment is set. The expounded material gives exhaustive description of the physical and thermodynamics phenomena flowings in the area of contact of circle. A manual is intended for students, graduate students and engineers-mechanics. |  | | Matyukha P.G. Diamond polishing with the electro-erosive managing operating on the working surface of circle / P.G. Matyukha, V.V. Poltovec'. - Donetsk : DONNTU, 2006. - 164 p. In a monograph on the basis of analysis of functioning of subsystems of cutting and managing actions, which make the polishing system with the management of working surface of circle parameters, and formulated basic principles of management of relief of working surface of instrument parameters, the executed description of conformities to law of functioning of cutting subsystems in time, subsoil of which is made by atematichni dependences for the calculation of component forces of cutting on a diamond-impregnated in any moment of time. Expounded methods of calculation of intensity of delete of zv''yazki and products of salting in the process of the managing operating on the working surface of circle on the set indexes of quality and minimum specific prime price of treatment. Developed method of determination of the optimum modes of polishing of hard-processing materials with the keruvannm parameters of working surface of circle by an electro-erosive method at polishing on hard and resilient charts. Materials of monograph are intended for research workers, teachers of educational establishments, specialists, in industry of engineer, students, at implementation of master's degree works and diploma projects. and also graduate students and doktorants. |  | |

Bases of theory of the thermal phenomena at polishing of details of machines: studies. manual / A.V. Yakimov, B.O. Tkachenko, S.G. Zymin, A.A. Yakimov, N.I. Reshetnev, A.M. Shintasov, V.P. Larshin. - O. : OSPU, 1997. - 272 p. In a train aid teplofizichekie tasks are systematized on the basis of classification of influence of geometrical forms, processed surfaces on the temperature field at polishing. The expounded material gives exhaustive description of mathematical receptions, in-use for the construction of function of Grin, and also carries certificate character. Manual is intended for students, graduate students and engineers-mechanics. |  | | Salov P.M. Principles of samoorganizacii of wear of diamond-impregnateds / P.M. Salov, B.A. Kravchenko. - Samara: Samar. state techn. un-y, 2001. - 118 p. In a book a necessity is first grounded of giving circles, to workings with a serve along their longitudinal formative, optimal forms of longitudinal section. In basis of theoretical developments on determination of ravnoiznosnykh forms principles of samoorganizacii at the wear of kontaktiruemykh bodies are fixed. The naturally set ravnoiznosnye forms of circles, workings with serves on a passage-way along their longitudinal formative are analytically certain. The roles of edge wear and factor of the natural earning extra money are exposed on the form of circle. Methods are expounded on determination of the required calculation parameters. Financial viability of maintenance of conservative form of circle is well-proven by renewal at a correction or cleaning of mikroprofilya and delete of unfavorable waviness. A book is intended for ingineer-technical and scientific workers, and also useful students and graduate students, specialize in area of materials cutting.

|  | | Tergan V.S. Flat polishing / V.S. Tergan, B.S. Liberman. - M. : High school, 1969. - 284 p., il. A book contains taking on bases of polishing business, technologies of the flat polishing, description of devices and mechanisms of basic types of ploskoshlifoval'nykh machine-tools, descriptions of diamond-impregnateds, description of universal and special adaptations for the flat polishing. In addition, in a book material is plugged about the type polishing, the questions of economy, organization of production, and also accident and labour protection prevention are lighted up. A book is a train aid for preparation in city professional-technical schools of polishers on ploskoshlifoval'nykh machine-tools.

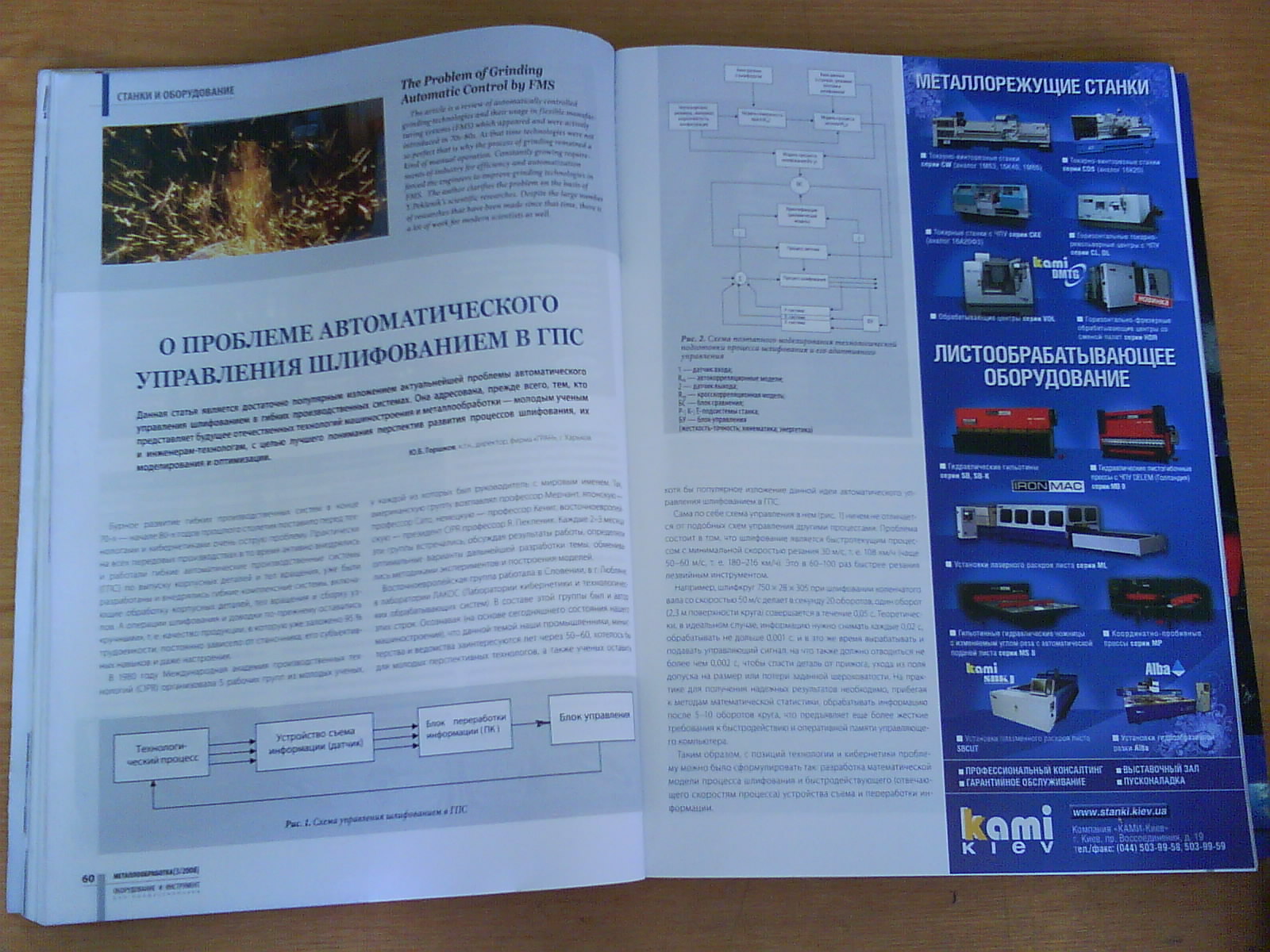

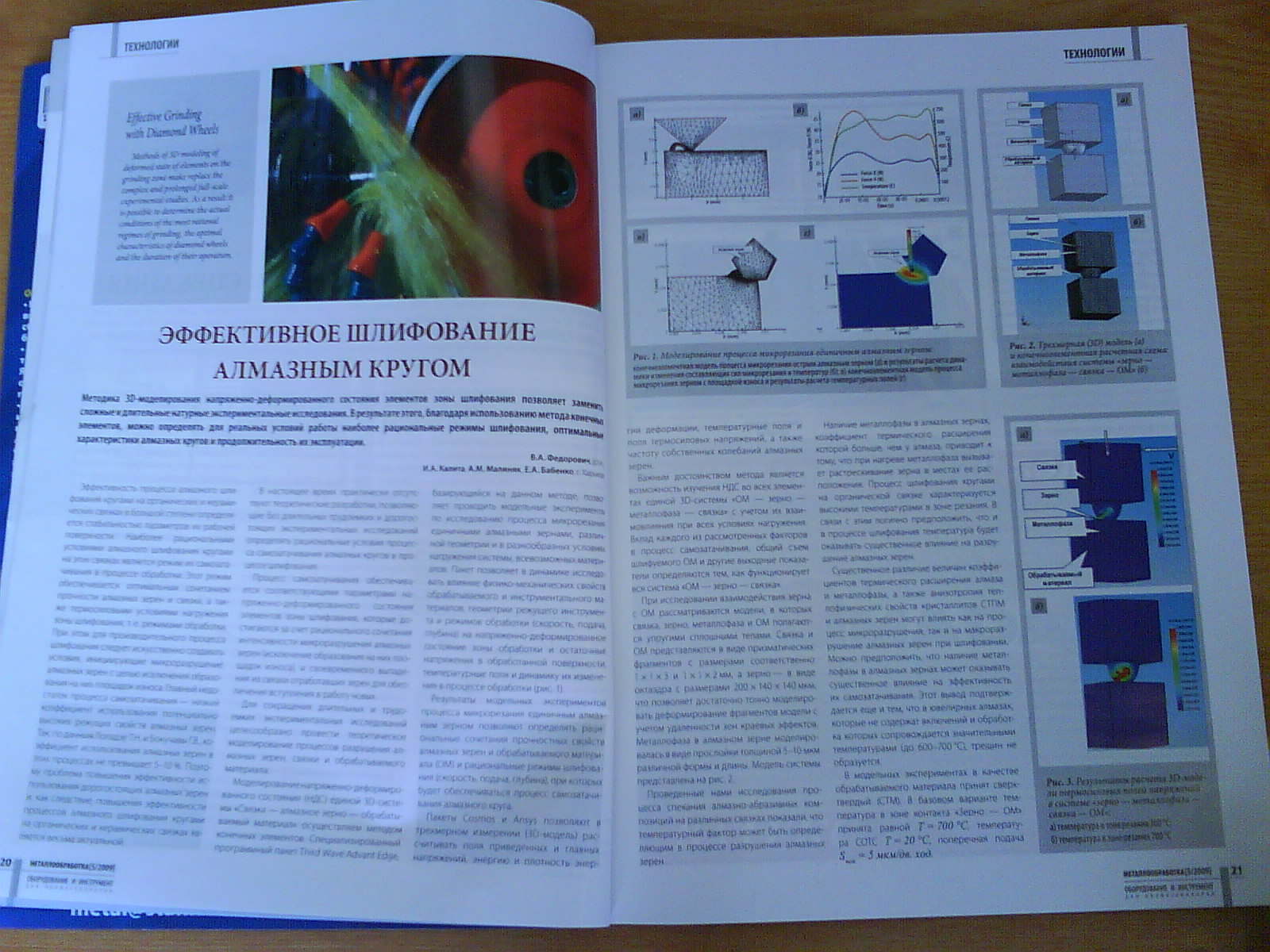

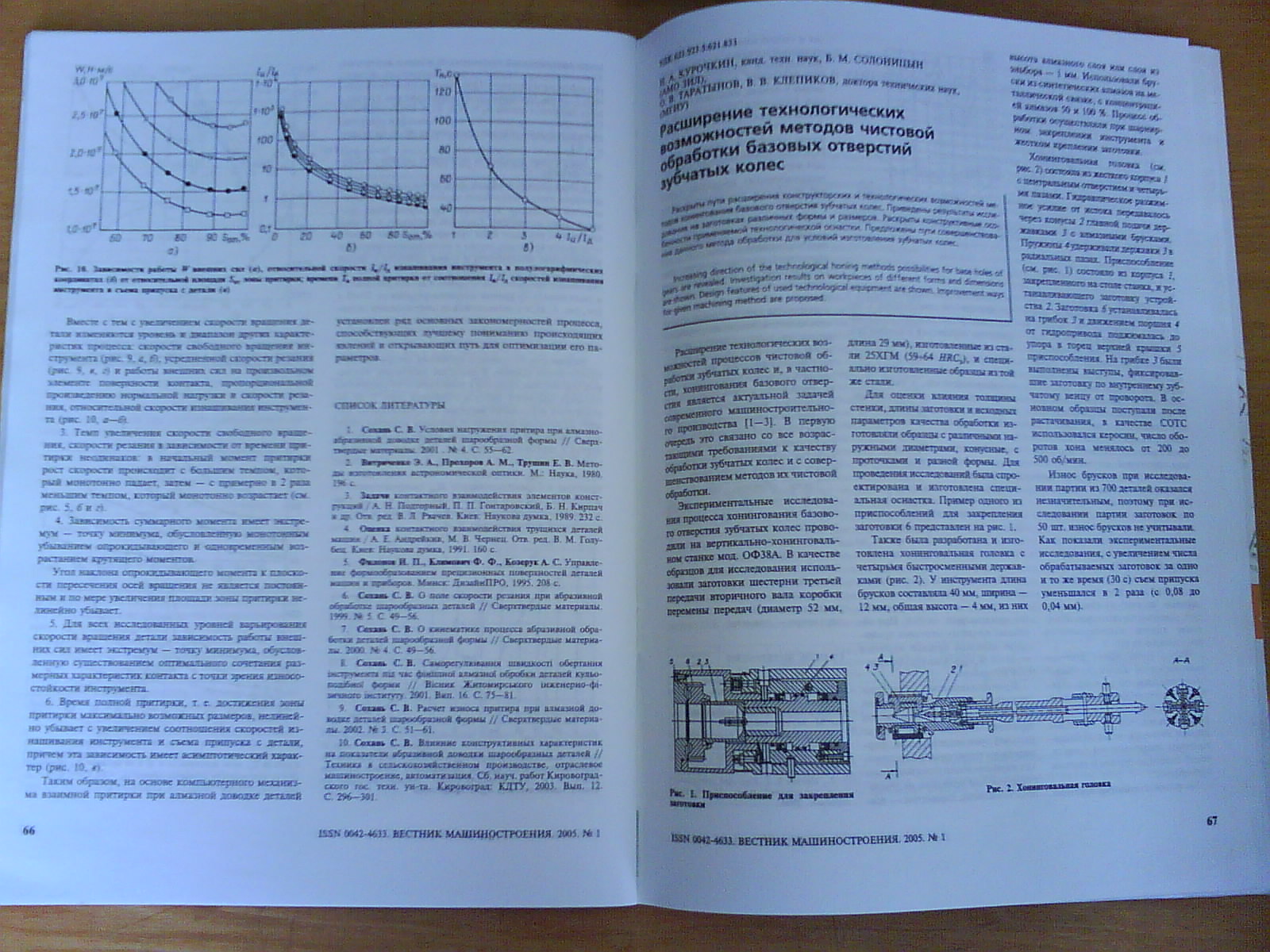

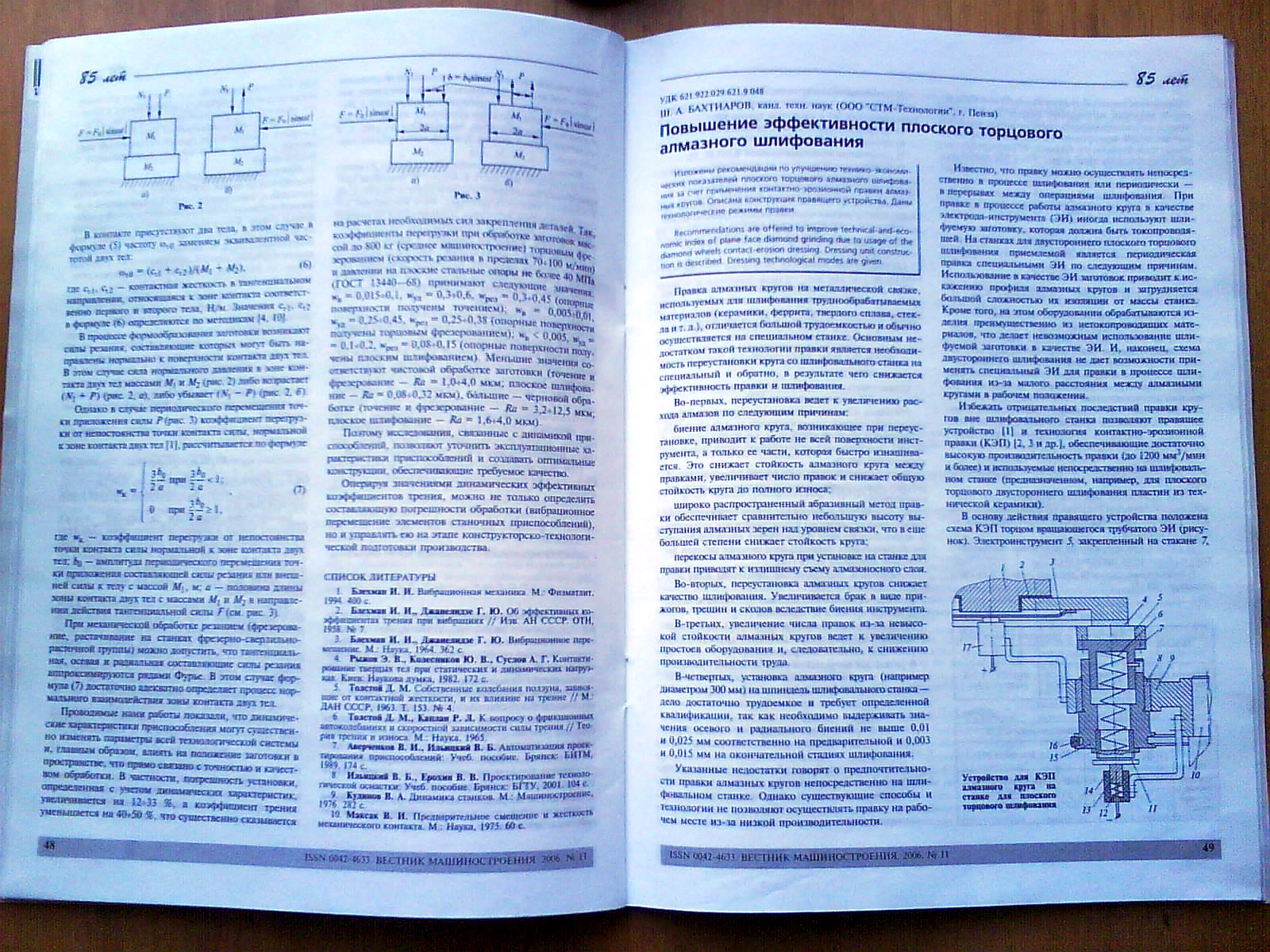

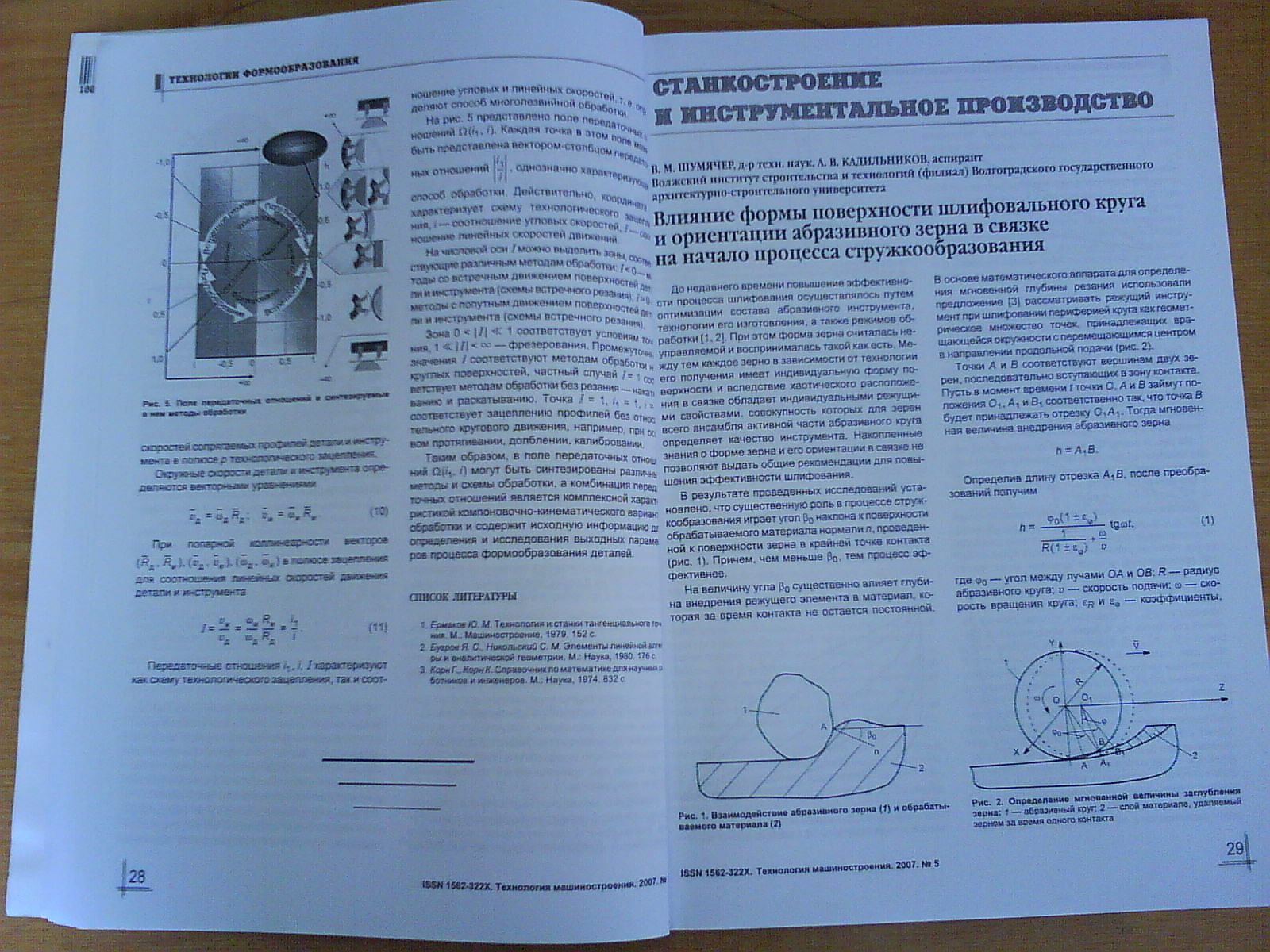

|  | | Uzunyan M.D. Diamond-spark polishing of carboloies / M.D. Uzunyan. - Kh. : NTU «KHPI», 2003. - 359 p. The results of researches of the diamond-spark polishing of carboloies are resulted in a book. His efficiency is rotined, methodical approaches, features of co-operation of the processed material, are described with diamond circles. Practical recommendations are expounded on development and introduction of technology of polishing of carboloies. A book is intended for the ingineer-technical workers of industrial enterprises, NII, can be useful the students of machine-building specialities of institutes of higher. |  | | Yakimov A.V. Diamond treatment: studies. manual / A.V. Yakimov, F.V. Novikov. - K. : IZMN, 1996. - 168 p. The physical model of process of diamond treatment and exposure of conformities to law of change of physical parameters is considered. The dynamic model of process of the irregular polishing, terms of origin of self-reactance resonance, essence of the electro-diamond polishing and method of management a dynamic structure, is analysed. Physical conformities to law are described diamond-spark that electrochemical polishing. A manual is intended for the students of all forms of teaching of machine-building specialities. |  | | Yakimov A.V. High-performance treatment abrasive-diamond instruments / A.V. Yakimov, F.V. Novikov, A.A. Yakimov. - K. : Technique, 1993. - 152 p. The methods of management the productivity of polishing process are considered in a train aid. Dependence of geometrical and kinematics parameters of polishing circles is rotined from sverkhtverdykh materials from the terms of cutting. Connection of the temperature field is set with temporal termouprugimi and termoplasticheskimi tensions at the irregular polishing of details with coverages. Large attention is spared influence of chemical composition of the processed material on treschinoobrazovanie. The technical features of polishing elastic irregular diamond-abrasive instruments are considered. A manual is intended for the students of institutes of higher of machine-building specialities. |  | | Yakimov A.V. Irregular polishing / A.V. Yakimov. - K.: High school, 1986. - 175 p. Professor A.V. Yakimov in the book presented the results of complex research of process of abrasive-diamond treatment of details instruments by an irregular working surface. In a book theoretical and experimental information of on principle new scientific direction is generalized on a management the physics-mechanical state of superficial layer of details. Technology of making and exploitation of instruments is Given with an irregular working surface, to on the rational use of financial, raw material, labour and power resources. | | | | | | | | | | About the problem of automatic control polishing in GPS // Equipment and instrument for professionals. - 2008. - № 3. - P. 60-62. |  | |  | | | | | | Effective polishing diamond a circle // Equipment and instrument for professionals. - 2009. - №5. - P. 20-23. |  | |  | | | | | | Expansion of technological possibilities of methods of clean treatment of the base openings of gear-wheels is // Announcer of ingineer. - 2005. - №1. - P. 66-67. |  | |  | | | | | | Increase of efficiency of the flat cuttof diamond polishing is // Announcer of engineer. - 2006. - № 11. - P. 49-51. |  | |  | | | | | | | | | | MAINA - without compromiss quality, polished expierence in area of power transmissions //Worlk of technique and technologies. - 2009. - № 10. - P. 24 - 25. |  | |  | | | | | | Influence of form of surface of diamond-impregnated and orientation of abrasive grain in a copula on beginning of process struzhkoobrazovania // Тechnology of ingineer. - 2007. - № 5. - P. 29. |  | |  |

|